Sizing Saw Blades DP for Segment Hoggers "ES-FA"

Article

Description

Machine / Application

- double end tenoners

- edge trimming machines

- for chip-free sizing of raw, melamine-, paper-, HPL-laminated, foiled and veneered panels

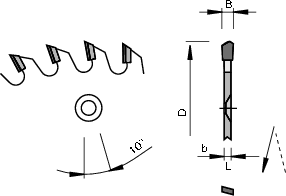

Design

- tooth configuration: top bevel with chamfer and face shear "ES-FA"

- saw blade with equal tooth pitch

- n max = 9,000 min-1 with Ø 200 mm

- n max = 7,200 min-1 with Ø 250 mm

- resharpenable area 4 mm; sides of teeth can be resharpened

Advantages

Notes

- application against feed

- for scoring/hogging (RZ) and double hogging (DZ) process

- for combination with LEUCO Segment Hoggers: Ø 80 on Segment Hoggers with standard bushing / Ø 100 on Segment Hoggers for s-System

- the specified feed rates are based on n = 6,000 min-1

- sense of rotation see drawing

|

Ø D

[mm] |

B

[mm] |

b

[mm] |

Ø d

[mm] |

Z | L/R |

nmax

[min-1] |

Feed DZ

[m/min] |

Feed RZ

[m/min] |

Ident-No. | Comp./ Inqu. | |

|---|---|---|---|---|---|---|---|---|---|---|---|

|

Dimensions entered are not listed?

available from stock |

|||||||||||

| 200 | 4,0 | 2.8 | 80 | 24 | L | 9,000 | 25 | 15 | 170397 | ||

| 200 | 4,0 | 2.8 | 80 | 24 | R | 9,000 | 25 | 15 | 170398 | ||

| 200 | 4,0 | 2.8 | 80 | 28 | L | 9,000 | 30 | 17,5 | 170399 | ||

| 200 | 4,0 | 2.8 | 80 | 28 | R | 9,000 | 30 | 17,5 | 170400 | ||

| 200 | 4,0 | 2.8 | 80 | 32 | L | 9,000 | 32,5 | 20 | 170401 | ||

| 200 | 4,0 | 2.8 | 80 | 32 | R | 9,000 | 32,5 | 20 | 170402 | ||

| 200 | 4,0 | 2.8 | 80 | 36 | L | 9,000 | 35 | 22,5 | 170403 | ||

| 200 | 4,0 | 2.8 | 80 | 36 | R | 9,000 | 35 | 22,5 | 170404 | ||

| 200 | 4,0 | 2.8 | 80 | 40 | L | 9,000 | 40 | 25 | 170405 | ||

| 200 | 4,0 | 2.8 | 80 | 40 | R | 9,000 | 40 | 25 | 170406 | ||

| 200 | 4,0 | 2.8 | 80 | 44 | L | 9,000 | 45 | 27,5 | 170407 | ||

| 200 | 4,0 | 2.8 | 80 | 44 | R | 9,000 | 45 | 27,5 | 170408 | ||

| 200 | 4,0 | 2.8 | 80 | 48 | L | 9,000 | 50 | 30 | 170409 | ||

| 200 | 4,0 | 2.8 | 80 | 48 | R | 9,000 | 50 | 30 | 170410 | ||

| 250 | 4,0 | 2.8 | 80 | 24 | L | 7,200 | 25 | 15 | 170495 | ||

| 250 | 4,0 | 2.8 | 80 | 24 | R | 7,200 | 25 | 15 | 170496 | ||

| 250 | 4,0 | 2.8 | 80 | 30 | L | 7,200 | 32,5 | 20 | 170497 | ||

| 250 | 4,0 | 2.8 | 80 | 30 | R | 7,200 | 32,5 | 20 | 170498 | ||

| 250 | 4,0 | 2.8 | 80 | 36 | L | 7,200 | 40 | 25 | 170499 | ||

| 250 | 4,0 | 2.8 | 80 | 36 | R | 7,200 | 40 | 25 | 170500 | ||

| 250 | 4,0 | 2.8 | 80 | 42 | L | 7,200 | 45 | 27,5 | 170501 | ||

| 250 | 4,0 | 2.8 | 80 | 42 | R | 7,200 | 45 | 27,5 | 170502 | ||

| 250 | 4,0 | 2.8 | 80 | 48 | L | 7,200 | 50 | 30 | 170503 | ||

| 250 | 4,0 | 2.8 | 80 | 48 | R | 7,200 | 50 | 30 | 170504 | ||

| 250 | 4,0 | 2.8 | 80 | 54 | L | 7,200 | 55 | 35 | 170505 | ||

| 250 | 4,0 | 2.8 | 80 | 54 | R | 7,200 | 55 | 35 | 170506 | ||

| 250 | 4,0 | 2.8 | 80 | 60 | L | 7,200 | 60 | 40 | 170507 | ||

| 250 | 4,0 | 2.8 | 80 | 60 | R | 7,200 | 60 | 40 | 170508 | ||

| 250 | 4,0 | 2.8 | 80 | 66 | L | 7,200 | 65 | 45 | 170509 | ||

| 250 | 4,0 | 2.8 | 80 | 66 | R | 7,200 | 65 | 45 | 170510 | ||

| 250 | 4,0 | 2.8 | 100 | 24 | L | 7,200 | 25 | 15 | 170621 | ||

| 250 | 4,0 | 2.8 | 100 | 24 | R | 7,200 | 25 | 15 | 170622 | ||

| 250 | 4,0 | 2.8 | 100 | 30 | L | 7,200 | 32,5 | 20 | 170623 | ||

| 250 | 4,0 | 2.8 | 100 | 30 | R | 7,200 | 32,5 | 20 | 170624 | ||

| 250 | 4,0 | 2.8 | 100 | 36 | L | 7,200 | 40 | 25 | 170625 | ||

| 250 | 4,0 | 2.8 | 100 | 36 | R | 7,200 | 40 | 25 | 170626 | ||

| 250 | 4,0 | 2.8 | 100 | 42 | L | 7,200 | 45 | 27,5 | 170627 | ||

| 250 | 4,0 | 2.8 | 100 | 42 | R | 7,200 | 45 | 27,5 | 170628 | ||

| 250 | 4,0 | 2.8 | 100 | 48 | L | 7,200 | 50 | 30 | 170629 | ||

| 250 | 4,0 | 2.8 | 100 | 48 | R | 7,200 | 50 | 30 | 170630 | ||

| 250 | 4,0 | 2.8 | 100 | 54 | L | 7,200 | 55 | 35 | 170631 | ||

| 250 | 4,0 | 2.8 | 100 | 54 | R | 7,200 | 55 | 35 | 170632 | ||

| 250 | 4,0 | 2.8 | 100 | 60 | L | 7,200 | 60 | 40 | 170633 | ||

| 250 | 4,0 | 2.8 | 100 | 60 | R | 7,200 | 60 | 40 | 170634 | ||

| 250 | 4,0 | 2.8 | 100 | 66 | L | 7,200 | 65 | 45 | 170635 | ||

| 250 | 4,0 | 2.8 | 100 | 66 | R | 7,200 | 65 | 45 | 170636 | ||

| 250 | 4,0 | 2.8 | 100 | 72 | L | 7,200 | 70 | 50 | 170637 | ||

| 250 | 4,0 | 2.8 | 100 | 72 | R | 7,200 | 70 | 50 | 170638 | ||